by Jeffrey Justin K | Jun 18, 2013 | Product News

The universally applicable oven is our classic appliance for temperature control in science, research and material tests in industry. The technologically perfected masterpiece made of high-quality, hygienic, easy-to-clean stainless steel leaves nothing to be desired in terms of ventilation and control technology, overtemperature protection and precisely tuned heating technology.

On this page, you can find all the essential technical data on our universal oven. Our customer relations team will be pleased to help if you want further information. If you should require a customised special solution, please contact our technical specialists atmyAtmoSAFE(at)memmert.com.

- natural convection

- adjustment of pre-heated fresh air admixture by air flap control in 10% steps

- vent connection with restrictor flap

- adaptive multifunctional digital PID-microprocessor controller with high-definition TFT-colour display

- self-diagnostics for fault analysis

- 1 Pt100 sensor DIN class A in 4-wire-circuit

- digital timer adjustable from 1 minute to 99 days, 23 hours

- parameters adjustable on ControlCOCKPIT: temperature (Celsius or Fahrenheit), air flap position, programme time, time zones, summertime/wintertime

- SetpointWAIT function – the process time does not start until the set temperature is reached

- Setting of languages on ControlCOCKPIT: German/English/Spanish/French

- resolution of display for setpoint values 0.1°C up to 99.9°C, 0.5°C from 100°C and for actual values 0.1°C (LED)

- calibration facility directly at ControlCOCKPIT for three freely selectable temperature values

- programme stored in case of power failure

- incl. works calibration certificate for +160°C

- adjustable electronic overtemperature monitor and mechanical temperature limiter TB, protection class 1 according to DIN 12 880 to switch off the heating approx. 20°C above nominal temperature

- w x h x d: 824 x 1186 x 684 mm

- fully insulated stainless steel door with 2-point locking (compression door lock)

- rear zinc-plated steel

- w x h x d: 640 x 800 x 500 mm, 256 l

- easy-to-clean interior,made of stainless steel,reinforced by deep drawn ribbing with integrated and protected large-area heating on four sides

- 2 stainless steel grids

- Max. loading of chamber: 300 kg

- min. 5°C above ambient up to +300°C

- 230 V (+/- 10%), 50/60 Hz / approx. 3.400 W

- 115 V (+/- 10%), 50/60 Hz / approx. 2.200 W

- net weight approx. 110 kg

- gross weight carton approx. 166 kg

- dimensions approx.:

carton w x h x d: 93 x 153 x 92 cm

- the appliances must be transported upright

- Federal Republic of Germany

by Jeffrey Justin K | Jun 18, 2013 | Product News

The universally applicable oven is our classic appliance for temperature control in science, research and material tests in industry. The technologically perfected masterpiece made of high-quality, hygienic, easy-to-clean stainless steel leaves nothing to be desired in terms of ventilation and control technology, overtemperature protection and precisely tuned heating technology.

On this page, you can find all the essential technical data on our universal oven. Our customer relations team will be pleased to help if you want further information. If you should require a customised special solution, please contact our technical specialists atmyAtmoSAFE(at)memmert.com.

- forced air circulation by 2 quiet air turbines, adjustable in 10% steps

- adjustment of pre-heated fresh air admixture by air flap control in 10% steps

- vent connection with restrictor flap

- adaptive multifunctional digital PID-microprocessor controller with high-definition TFT-colour display

- self-diagnostics for fault analysis

- 1 Pt100 sensor DIN class A in 4-wire-circuit

- digital timer adjustable from 1 minute to 99 days, 23 hours

- parameters adjustable on ControlCOCKPIT: temperature (Celsius or Fahrenheit), fan speed, air flap position, programme time, time zones, summertime/wintertime

- SetpointWAIT function – the process time does not start until the set temperature is reached

- resolution of display for setpoint values 0.1°C up to 99.9°C, 0.5°C from 100°C and for actual values 0.1°C (LED)

- calibration facility directly at ControlCOCKPIT for three freely selectable temperature values

- programme stored in case of power failure

- incl. works calibration certificate for +160°C

- adjustable electronic overtemperature monitor and mechanical temperature limiter TB, protection class 1 according to DIN 12 880 to switch off the heating approx. 20°C above nominal temperature

- w x h x d: 1224 x 1726 x 784 mm

- fully insulated stainless steel doors with 2-point locking (compression door lock)

- rear zinc-plated steel

- on lockable castors

- w x h x d: 1040 x 1200 x 600 mm, 749 l

- easy-to-clean interior,made of stainless steel,reinforced by deep drawn ribbing with integrated and protected large-area heating on four sides

- 2 stainless steel grids

- Max. loading of chamber: 300 kg

- min.10°C above ambient up to +300°C

- 400 V (+/ 10%), 3 phases/N, 50/60 Hz / approx. 7.000 W

- net weight approx. 217 kg

- gross weight carton approx. 292 kg

- dimensions approx.:

carton w x h x d: 133 x 192 x 105 cm

- the appliances must be transported upright

- Federal Republic of Germany

by Jeffrey Justin K | Jun 18, 2013 | Product News

The universally applicable oven is our classic appliance for temperature control in science, research and material tests in industry. The technologically perfected masterpiece made of high-quality, hygienic, easy-to-clean stainless steel leaves nothing to be desired in terms of ventilation and control technology, overtemperature protection and precisely tuned heating technology.

On this page, you can find all the essential technical data on our universal oven. Our customer relations team will be pleased to help if you want further information. If you should require a customised special solution, please contact our technical specialists atmyAtmoSAFE(at)memmert.com.

- forced air circulation by quiet air turbine, adjustable in 10% steps

- adjustment of pre-heated fresh air admixture by air flap control in 10% steps

- vent connection with restrictor flap

- adaptive multifunctional digital PID-microprocessor controller with high-definition TFT-colour display

- self-diagnostics for fault analysis

- 1 Pt100 sensor DIN class A in 4-wire-circuit

- digital timer adjustable from 1 minute to 99 days, 23 hours

- parameters adjustable on ControlCOCKPIT: temperature (Celsius or Fahrenheit), fan speed, air flap position, programme time, time zones, summertime/wintertime

- SetpointWAIT function – the process time does not start until the set temperature is reached

- resolution of display for setpoint values 0.1°C up to 99.9°C, 0.5°C from 100°C and for actual values 0.1°C (LED)

- calibration facility directly at ControlCOCKPIT for three freely selectable temperature values

- programme stored in case of power failure

- incl. works calibration certificate for +160°C

- adjustable electronic overtemperature monitor and mechanical temperature limiter TB, protection class 1 according to DIN 12 880 to switch off the heating approx. 20°C above nominal temperature

- w x h x d: 585 x 707 x 434 mm

- fully insulated stainless steel door with 2-point locking (compression door lock)

- rear zinc-plated steel

- w x h x d: 400 x 320 x 250 mm, 32 l

- easy-to-clean interior,made of stainless steel,reinforced by deep drawn ribbing with integrated and protected large-area heating on four sides

- 1 stainless steel grid

- Max. loading of chamber: 60 kg

- min.10°C above ambient up to +300°C

- 230 V (+/- 10%), 50/60 Hz / approx. 1.600 W

- 115 V (+/- 10%), 50/60 Hz / approx. 1.600 W

- net weight approx. 48 kg

- gross weight carton approx. 59 kg

- dimensions approx.:

carton w x h x d: 69 x 96 x 66 cm

- the appliances must be transported upright

- Federal Republic of Germany

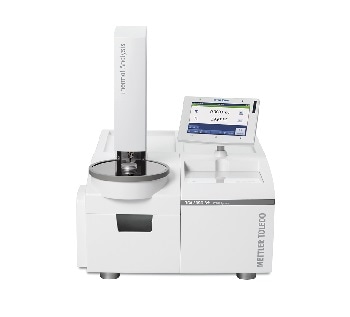

by Jeffrey Justin K | Jun 17, 2013 | Product News

The heart of a TGA is the balance cell. Our TGA instruments use the world’s best micro and ultra-micro balances. By using one of the three removable sensor types the TGA/DSC 1 simultaneously measures heat flow in addition to weight change. Thanks to its modular design, the TGA/DSC 1 is the ideal instrument for manual or automated operation in production and quality assurance through to research and development.

- High resolution – ultra-microgram resolution over the whole measurement range

- DSC heat flow measurement – for simultaneous detection of thermal events

- Modular concept – tailor-made solutions for current and future needs

Innovative Technology

Features and Benefits of the TGA/DSC 1 – Thermogravimetric Analyzer

| METTLER TOLEDO ultra-micro balance – rely on the balance technology leader |

|

| Efficient automation – most reliable sample robot for high sample throughput |

|

| Wide measurement range – measure small and large sample masses and volumes |

|

| Broad temperature scale – analyze samples from ambient to 1600 °C |

|

| DSC heat flow measurement – for simultaneous detection of thermal events |

|

| Hyphenated techniques – evolved gas analysis using MS and FTIR |

|

| Modular concept – tailor-made solutions for current and future needs |

|

Specifications – TGA/DSC 1 – Thermogravimetric Analyzer

| Temperature range |

RT … 1100 °C or 1600 °C |

| Heating rate (LF/SF) |

0.02…150/250 K/min |

| Cooling: 1100 … 60 °C |

8.8 min |

| Balance resolution |

0.1/1 µg (depending on balance model) |

| Material Number(s) |

51142003 |

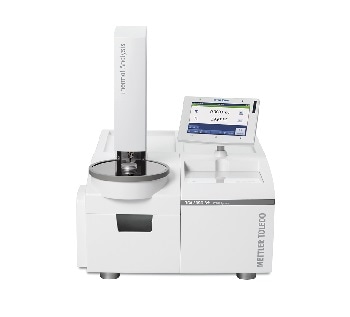

by Jeffrey Justin K | Jun 17, 2013 | Product News

The heart of a TGA is the balance cell. Our TGA instruments use the world’s best micro and ultra-micro balances. Thanks to its modular design, the TGA 1 is the ideal instrument for manual or automated operation in production and quality assurance through to research and development.

- High resolution – ultra-microgram resolution over the whole measurement range

- Wide measurement range – measure small and large sample masses and volumes

- Modular concept – tailor-made solutions for current and future needs

Innovative Technology

Features and Benefits of the TGA 1 – Thermogravimetric Analyzer

| METTLER TOLEDO ultra-micro balance – rely on the balance technology leader |

|

| Efficient automation – most reliable sample robot for high sample throughput |

|

| Wide measurement range – measure small and large sample masses and volumes |

|

| Broad temperature scale – analyze samples from ambient to 1100 °C |

|

| Hyphenated techniques – evolved gas analysis using MS and FTIR |

|

| Modular concept – tailor-made solutions for current and future needs |

|

Specifications – TGA 1 – Thermogravimetric Analyzer

| Temperature range |

RT … 1100 °C |

| Heating rate |

0.02…150/250 K/min |

| Cooling: 1100 … 60 °C |

8.8 min |

| Balance resolution |

0.1/1 µg (depending on balance model) |

| Material Number(s) |

30064763 |